| Brand | Vziman |

| Model NO. | Resin-insulated Dry Type Transformer 800KVA 1000KVA 1250KVA 1600KVA 2000KVA 2500KVA |

| Rated capacity | 2500kVA |

| Voltage grade | 10KV |

| Series | SC(B) |

Description:

Foil Coil: Adopting the entire section of copper foil, together with the F-class turn insulation, low voltage winding is wound by the special low-voltage foil winding machine. The foil coil resolves problems such as large short-circuit stress, ampere turn unbalance, poor heat dissipation, existing the winding spiral angle and unsteady manual welding quality due to low voltage and large current coil. At the same time, the end of winding is treated with cast resin, solidification to make shape, moisture-proof and anti-fouling, the lead for copper bar is welded by argon arc welding automatically.Temperature Control Device: the transformer adopts BWDK series of signal thermometer. The temperature components are embedded in the upper half of the low-voltage coil, can detect and display the temperature of separate phase coil automatically and continuously, also have the functions of over-temperature alarm and trip.

Feature:

Flame retardant, non-pollution, it can be installed directly in the load center.

Maintenance-free, easy to be installed, low operating costs.

The enclosure can be of Good moisture resistance, transformer can be put into operation without pre-drying under 100% humidity in the normal operation.

Low loss, light weight and small volume, low noise, good dissipation of heat, it can be 150% rated load operation under forced air cooling conditions.

Equipped with a complete temperature protection control system to provide reliable protection for the safe operation of transformers.

High reliability. The results of checking for the products that has been put into operation show that the reliability index has reached the international advanced level.

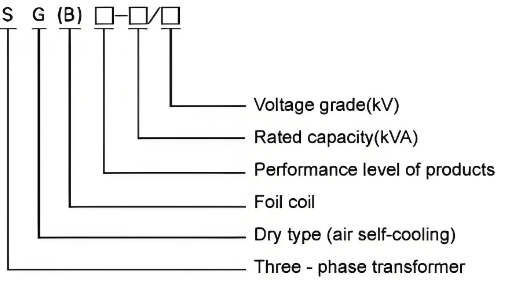

Model and Meaning:

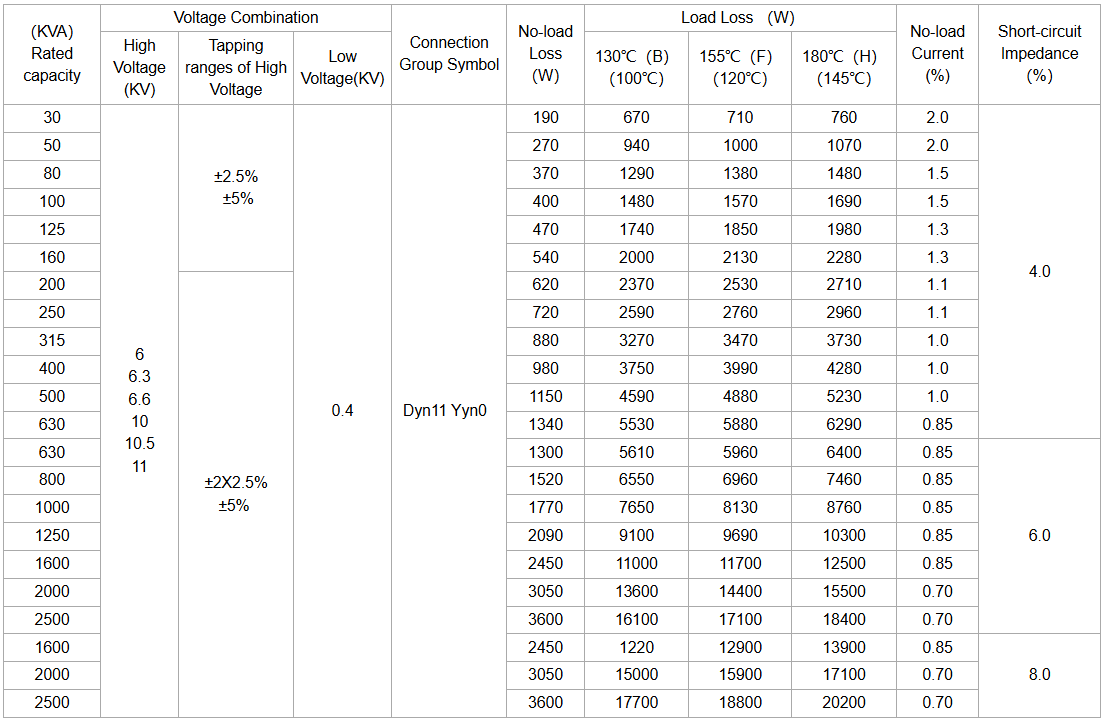

Parameter:

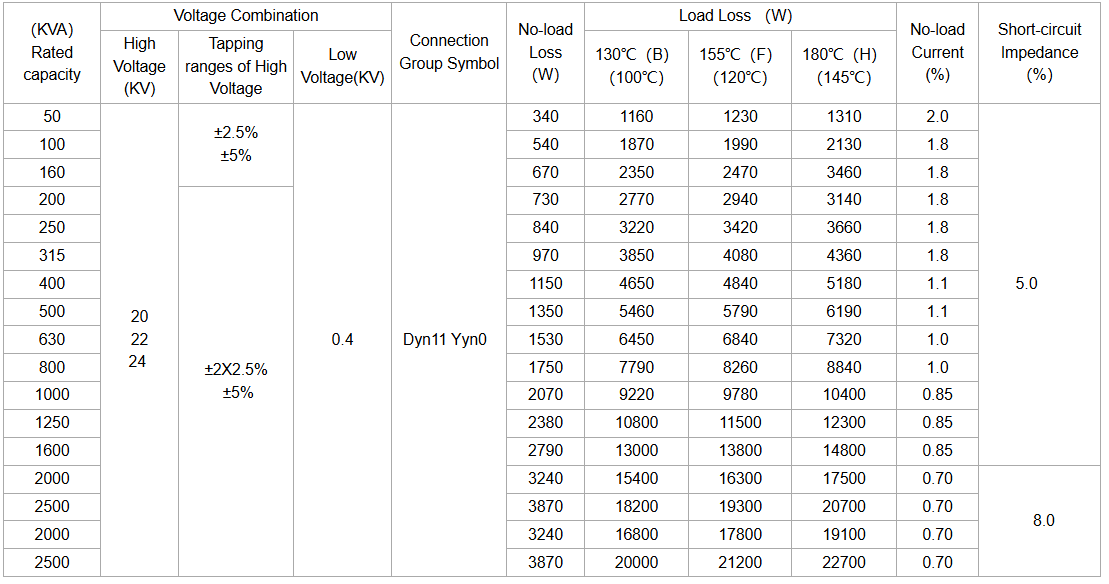

6kV, 10kV& 30kVA-2500kVA

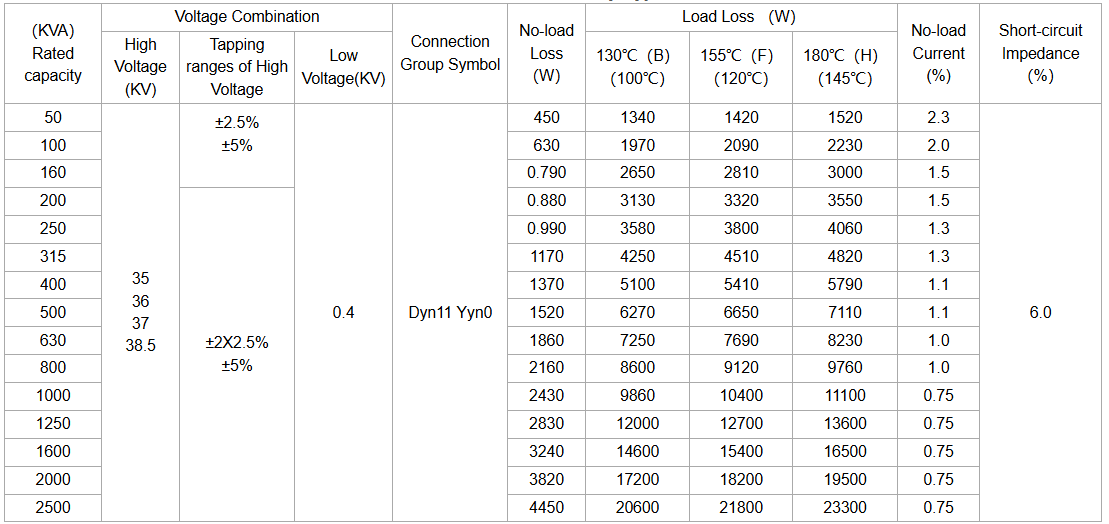

The load losses listed in the table are the values of the reference temperature for different insulation systems in parentheses; The load losses under other insulation system temperatures that are not included in the table should be according to their respective reference temperatures, the corresponding calculation is based on the"- 155 ℃ (F)" insulation system temperature data.

Notes: The Dimension and weight will be changed according to the requirements.

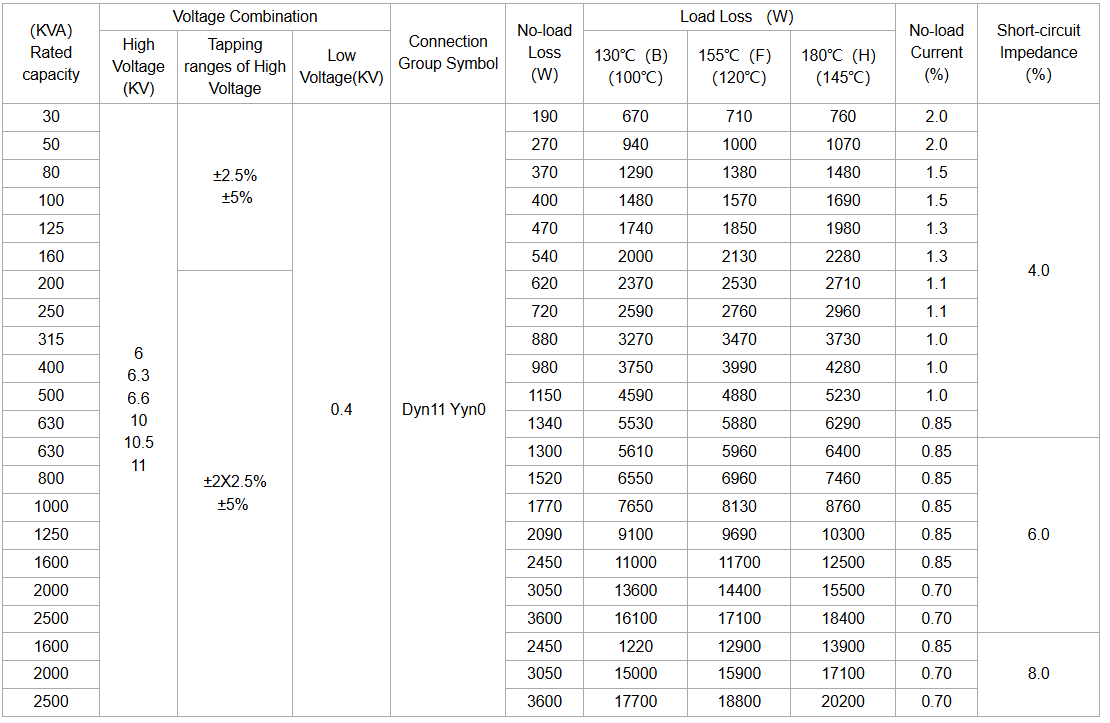

20kV & 50kVA-2500kVA

20kV & 50kVA-2500kVA

35kV & 50kVA-2500kVA

How resin-insulated dry-type transformers are cooled?

Natural air cooling is the most common cooling method, applicable to resin-insulated dry-type transformers with relatively low power. This method utilizes the natural convective air flow to dissipate heat.

Air Convection: During the operation of the transformer, heat will be generated, which will cause the temperature of the surrounding air to rise. The hot air will ascend, and the cold air will flow in to replace it, thus forming natural convection.

Heat Sinks: To enhance the heat dissipation effect, the outer surface of the transformer is usually designed with heat sinks or cooling fins to increase the surface area and improve the heat dissipation efficiency.

Ventilation Holes: The casing of the transformer is designed with ventilation holes to ensure air circulation and further improve the heat dissipation effect.

Forced air cooling is applicable to resin-insulated dry-type transformers with relatively high power. It improves the heat dissipation efficiency by forcing air to flow with the help of fans.

Fans: Fans are installed near the transformer. The fans blow the external cold air into the interior of the transformer to carry away the heat.

Air Duct Design: Air ducts are designed inside the transformer to ensure that the air can flow evenly through each heat-generating part, thus enhancing the heat dissipation effect.

Temperature Monitoring: Usually equipped with temperature sensors, it monitors the temperature of the transformer in real time. According to the temperature changes, it automatically controls the start and stop of the fans to achieve intelligent cooling.